STEP INTO XINGJINGCUI

走进我们

Foshan Jingcui Automation Equipment Co., Ltd. is a professional manufacturer of intelligent stamping automation equipment, located in Leliu Town, Shunde — a renowned hub for hardware and home appliances in Guangdong.

Established in 2003 (formerly known as Foshan Shunde Jingrui Hardware Machinery Equipment Co., Ltd.), the company has focused on developing intelligent stamping feeding systems for over 18 years. Through continuous experience and refinement, we have developed a full range of stamping automation solutions, including NC servo feeders, CNC aluminum foil feeders, high-speed roller feeders, automatic levelers, and vision feeders. Our products are widely used in the appliance, hardware, lighting, and home furnishing industries.

We offer customized solutions based on users’ production needs and provide complete production line support. Our goal is to help manufacturers achieve automation, save resources, and create tangible economic benefits.

22 Years Specializing in Stamping Automation

Full-cycle R&D, design, manufacturing, and sales of stamping automation feeders and precision mechanical parts

PRODUCTS

APPLICATION CASES

NC Oscillating Feed Automated Production Line

The NC Oscillating Feed Automated Production Line is widely used in sheet metal stamping for industries such as automotive and home appliances. This system utilizes a CNC system to precisely control material feeding and lateral oscillation, enabling efficient and flexible production of complex workpieces. It significantly improves material utilization and production efficiency, making it one of the core pieces of equipment in modern smart factories.

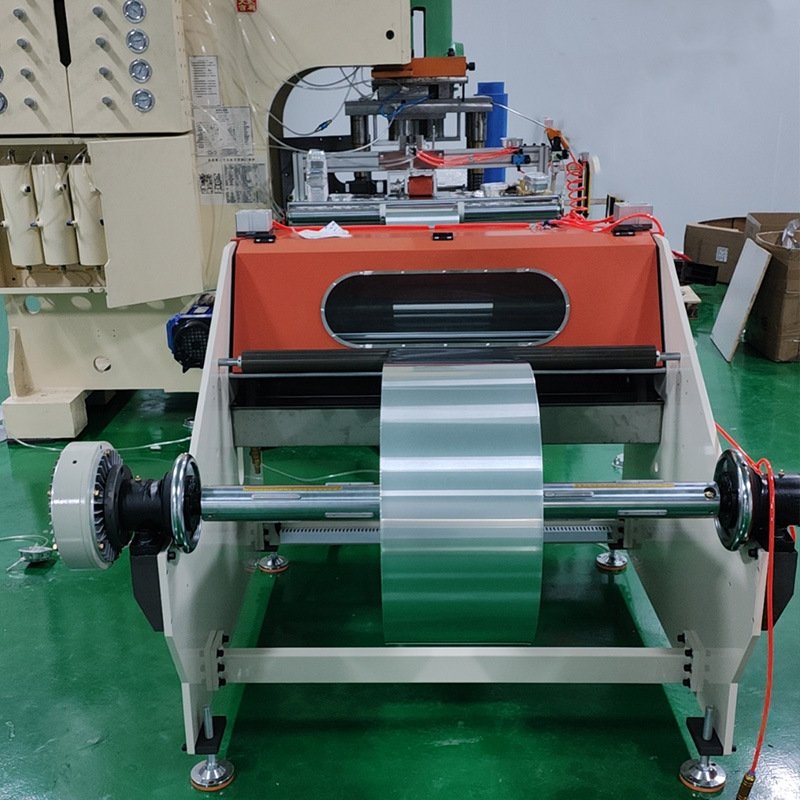

3-in-1 Automatic Feeding Production Line

The 3-in-1 Automatic Feeding Production Line has been successfully applied across multiple industrial sectors. This integrated equipment combines uncoiling, leveling, and feeding into a single system, effectively enhancing production efficiency and processing accuracy for products such as automotive parts and home appliance housings. It significantly reduces labor costs and provides a reliable automated solution for modern smart manufacturing.

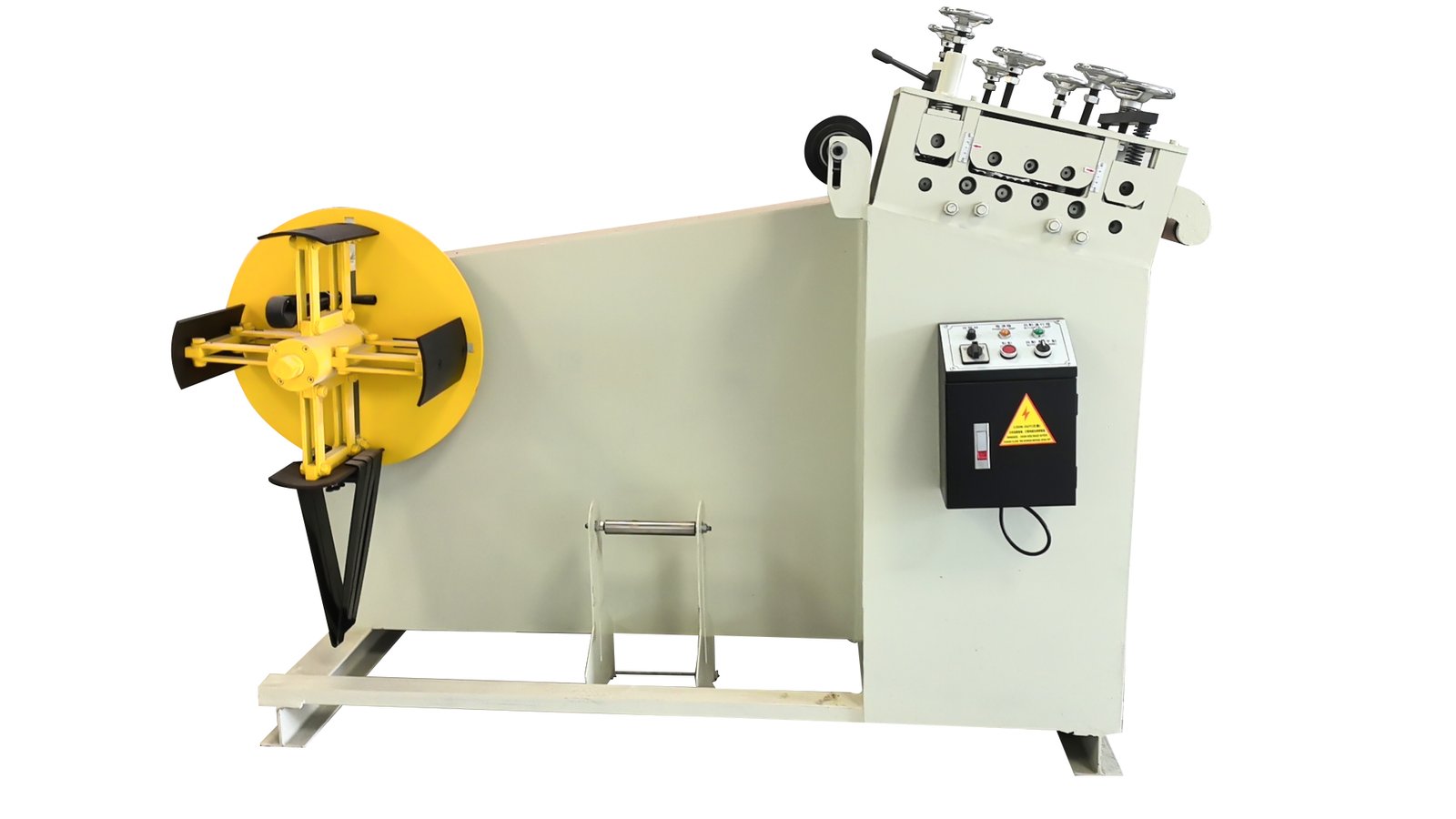

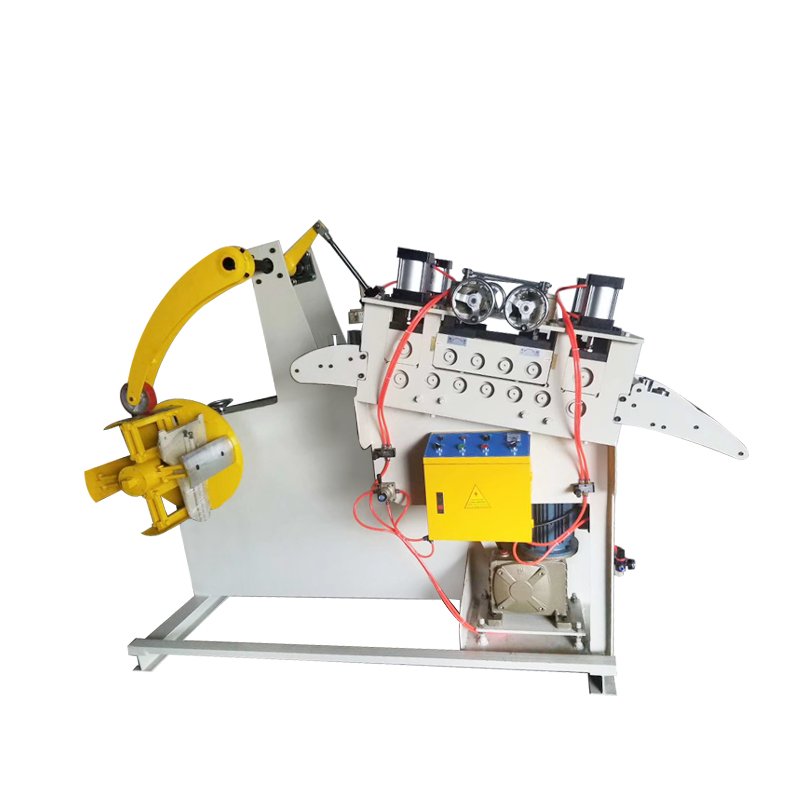

2-in-1 Uncoiling & Leveling Feeding Line

This production line plays a vital role in the furniture manufacturing industry. It integrates uncoiling and leveling functions within a single frame, efficiently processing coil materials such as cold-rolled sheets and galvanized sheets. Equipped with high-precision straightening rollers and a servo feeding system, it ensures the flatness of stamped parts and feeding accuracy, enabling automated and efficient production from raw material to finished product while effectively saving workshop space.

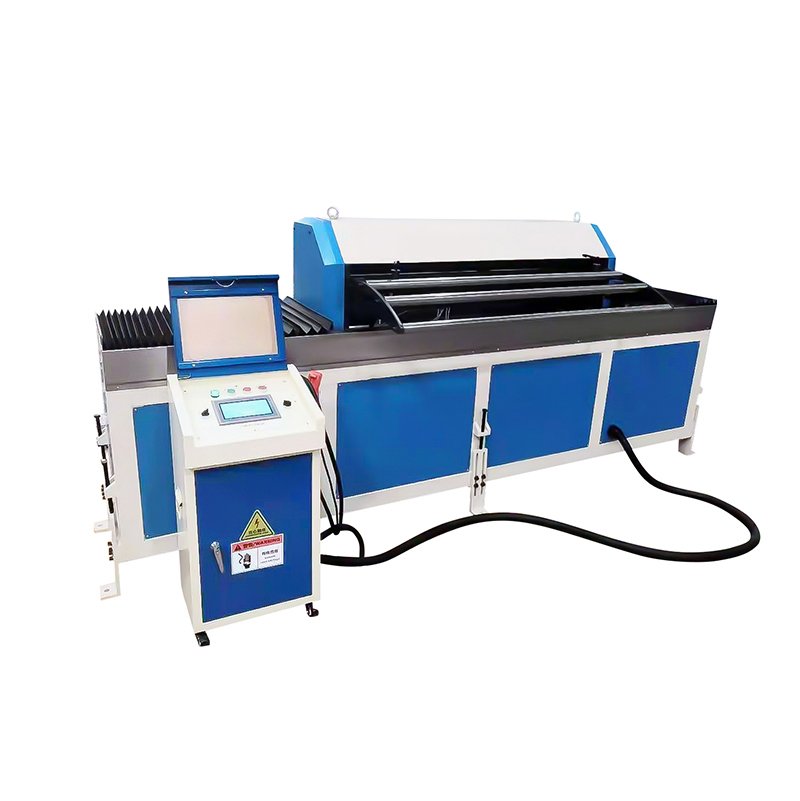

Sheet Feeding Automated Production Line

The Sheet Feeding Automated Production Line is widely used in industries such as metal processing and plastic products manufacturing. By incorporating automatic loading, precise positioning, and a continuous conveying system, this production line enables automated processing of sheet materials such as metal plates and plastic sheets. It significantly enhances production efficiency, ensures consistent product quality, and serves as essential foundational equipment for modern smart factories.

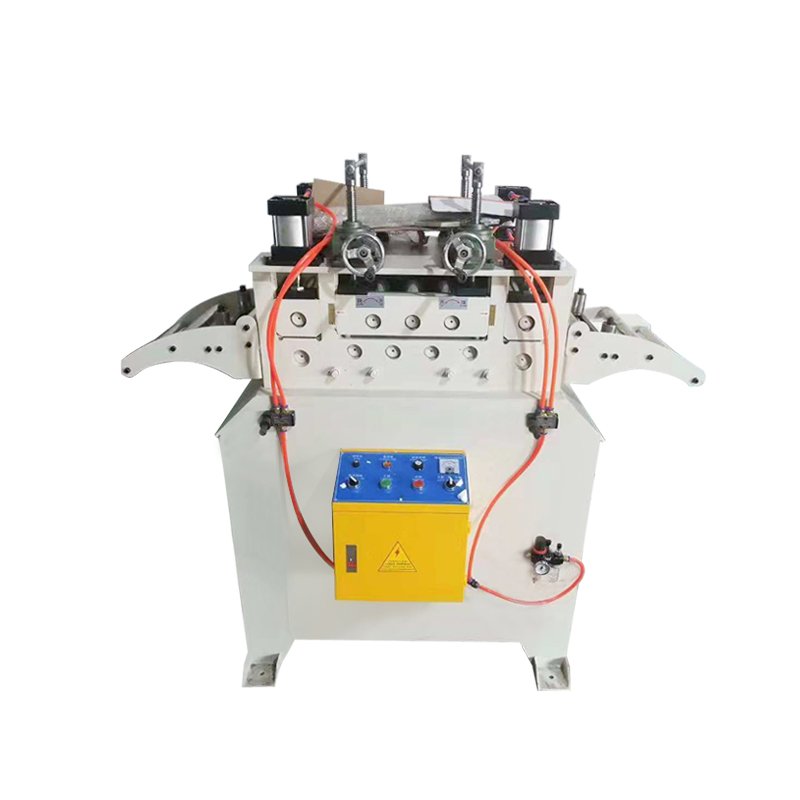

NC Roller Feed Automated Production Line

The NC Roller Feed Automated Production Line plays a central role in the field of metal sheet processing. Utilizing CNC-controlled rollers to accurately grip and feed metal coil materials, it works in tandem with stamping presses to achieve high-speed, high-precision automated production. This system effectively improves product consistency, reduces labor costs, and stands as one of the key pieces of equipment for enabling intelligent upgrades in the sheet metal stamping industry.

Join Us for a Shared Future

Through quality after-sales service, we have won strong customer trust and built a reputable brand in the industry.

National Service Hotline

+86 13715417442

CORE ADVANTAGES

Brand Strength

With an experienced team serving hundreds of clients

we possess decades of expertise in R&D and core technologies. We have a strong track record in manufacturing, especially in precision and complex automated assembly and machining.

01

High Efficiency, Low Cost

We provide tailored solutions and accept various non-standard machinery customization

Our standardized, high-efficiency production requires only one operator per machine, saving up to 15 labor costs while ensuring fast delivery.

02

Time-Saving, Effort-Reducing, Reliable Service

We offer full-process technical guidance and support

白底图-2.jpg)

.jpg)

.jpg)